As an Amazon Associate we earn from qualifying purchases.

Are you wondering whether you should purchase a band saw for your home woodworking shop? But what is a band saw good for? You’ll find there are many good reasons to consider adding one to your tools.

In several ways, band saws offer tremendous advantages over table saws, and are particularly useful for freehand cutting.

When considering buying a band saw, you will want to think about the following four benefits. You can also learn more about what a band saw is used for in my comprehensive article.

1. Versatility

A band saw’s versatility means that cutting curves for rounded tabletops and chair seats is relatively easy.

Certainly, band saws are excellent for the compound cutting required for furniture legs with curves.

Also, no other cutting tool can match the depth of cut you can get with a band saw.

This makes it possible to stack pieces of lumber, so you can cut several identical parts. In the same way, band saws make it possible to cut extremely thick single pieces of wood.

Band saws are also extremely handy when you’re attempting to thin down wide stock.

As for curves, the band saw is virtually indispensable for any non-rectilinear cuts like aprons or chair seats.

Get inspired with my list of bandsaw projects!

2. Operation

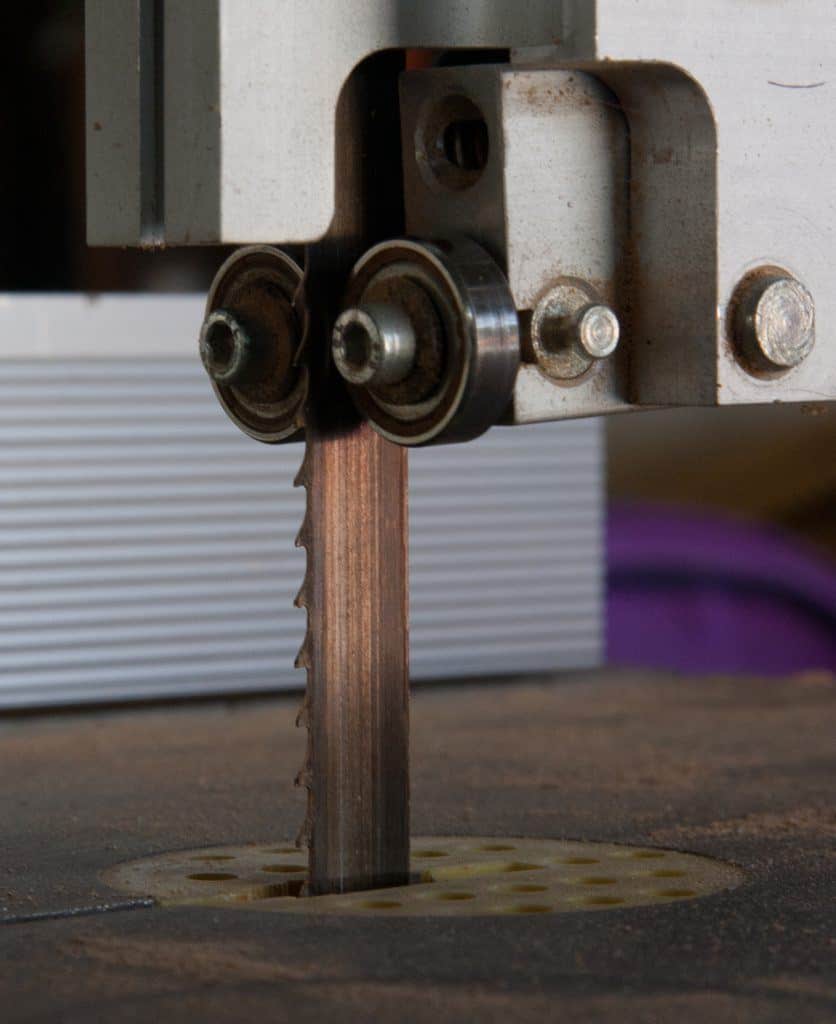

As the name band saw implies, this tool uses a blade in the shape of a closed loop. The wheels driving this loop are powered by a motor and a series of gears and pulleys.

Band saw blades usually travel anywhere from 2- 3000 ft./m. A band saw blade is located inside a metal case, with only the cutting area being exposed just above the saw’s worktable.

The best band saws on the market have powerful motors that allow them to cut through thick pieces of wood and metal. However, even cheap bandsaws have the power needed to cut through wood blocks and thin metal.

Blade guides are used to ensure the blade stays aligned. One guide is positioned under the tabletop, while the other guide can be adjusted to various heights over the table.

The tension on the band saw blade can be changed by adjusting the top wheel housing. Another kind of adjustment always found on a band saw ensures the blade always remains centered on the wheels.

3. Blade Options

Blades can be identified for the thickness of the blade (gauge), the number of teeth, and its overall width.

While some very wide blades are available for larger machines, most home workshops will have band saw blades roughly 1/8 inch-1/2 inch wide.

Depending on how you intend to use the blade, you can choose blades with different configurations and spacing of the teeth.

There is a one-to-one relationship between the curve you can cut with a blade and how narrow it is.

For instance, if you want to cut a radius that’s roughly 1/4 inch, you need a 1/8 inch wide blade. In the same way, cutting a 3/4 inch hole will mean using a 1/4 blade… and so on.

Do-it-yourselfers should keep in mind some things when purchasing band saw blades. Just like any other type of saw blade, blades with small teeth are best suited to cutting metal.

Blades with fewer, large teeth are best suited to wood. For rough cutting fairly thick timber, a band saw blade with coarse teeth works well. A blade with finer teeth produces smoother cuts.

4. Teeth Options

The types of teeth used on band saw blades also varies. Some are like a handsaw, with cutting teeth placed on either side that are interspersed with so called rakers unset teeth.

Blades equipped with raker teeth are more effective with wood.

Others use wavy set teeth. These teeth are positioned in a sequence where they are alternately closer and then further from the edge of the band.

This produces the wavy look. These wavy set teeth are often used for cutting metal rather than wood.

In situations where extremely smooth cuts are required or where plastics or ceramics are being cut, toothless blades are often used.

This type of blade works because the surface of the blade is bonded with tungsten carbide chips.

But keep in mind that if your band saw is fairly small, some of the above advice might not apply.

For instance, it’s often the case that smaller band saws will perform best using a much narrower blade than a wider one of say 1/2 inch or 3/4 inch.

One last point is that you should consider purchasing bimetal blades. These are blades where the teeth are made from a short strip of electron welded cobalt steel before the teeth were cut.

They’re much more long-lasting and far stronger.

Conclusion

Once you know how you want to use a band saw, the materials you want to cut, and how versatile a band saw is, the band saw just might be the next tool you need to add to your home workshop.