As an Amazon Associate we earn from qualifying purchases.

Scroll saws come with a wide variety of speed settings, which allow the blade to cut both fast and slow. These speeds are very important to cutting different types of materials, along with various types of cuts. I outline how fast a scroll saw can cut, and which speeds you want to use for which types of materials and cuts.

Contents

How Fast Does a Scroll Saw Cut?

A typical scroll saw cuts between 400 -800 strokes per minute at a slow speed and 1,200 – 1,800 SPM at high speed. The top scroll saws will be able to cover a wider range of speeds, whereas cheaper scroll saws will have a much more limited range of speed capabilities.

Slower speeds are better for cutting harder woods or intricate designs. Higher speeds are best for softer woods and metal.

Determining the Right Speed for Your Scroll Saw

Getting the speed right on your scroll saw can be a bit tricky.

- The faster the blade moves, the better the cut.

- If you go too slow, you lose control of the piece and break blades.

So in general, you want to go as fast as you can without losing control. Finding the right speed is a balancing act between the material, tension, and speed.

Set the Right Speed for Your Material

The material you want to cut determines the right speed, along with how intricate the pattern you want to use. Most scroll saws have variable numbered speed settings.

Slower speeds are best for harder materials, like:

- Hardwood

- Metal

- Bone

Higher speeds are better for softer materials, like:

- Softwood

- Leather

- Rubber

- Soft plastic

In general, the higher your speed, the cleaner your cut. There is no exact speed setting for different materials, instead, you have rules-of-thumb. Most experienced woodworkers do most of their cutting at roughly 50 and 75 percent of full speed.

For example, you might cut puzzle pieces at a speed setting of 6 or 7 because you’ll be using hardwood and making detailed cuts. If you are cutting stacks of ¼ plywood for fretwork, then you might go slower, say around 5.

When you move into cutting softer metals, you’ll need to use a slow speed.

The way to find the right speed is to start a little slower and then turn up the dial on the speed until you are cutting at the highest possible speed while maintaining control of the cut. As your blade wears out, you might set the speed higher still.

Scroll Saw Blade Tension and Alignment

Along with speeds, understanding your scroll saw’s blade tension and alignment will allow you to make precise and accurate cuts.

Blade Tension

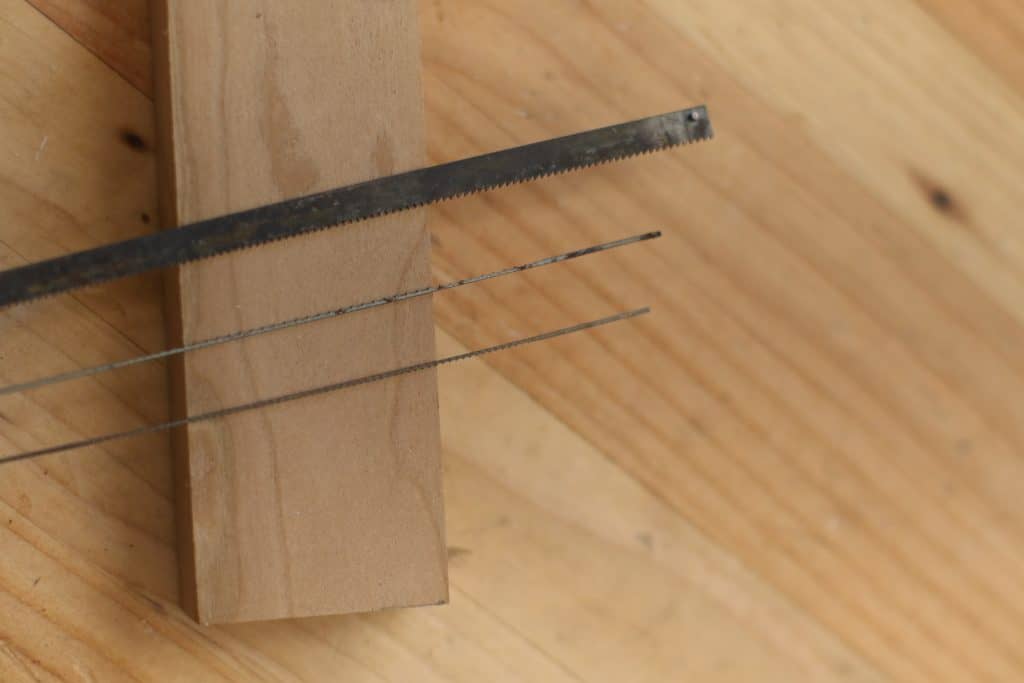

The first thing you do to begin a project on a scroll saw is to set the blade tension. You may need to practice with a few saw blades to get a sense of the right tension.

If the tension is too high, the blade will snap. On the other hand, low tension will cause the blade to bend and possibly break. A correctly tensioned saw blade will make a musical note when it is plucked. You should also feel resistance from the blade when you pluck the back of it.

Make practice cuts on scrap pieces of material and take notice of how often your blades are breaking. With practice, you will learn how to set the tension of your scroll saw blades.

Alignment and Squaring

A scroll saw does not need to be perfectly aligned and squared because the C arm can swing and move in different directions to follow curves and patterns. However, most square saws do come with inserts to help you align the saw and your materials.

If you are cutting several identical pieces, then squaring becomes more important. The main alignment you need to worry about it setting up your table to line up with a 90° angle.

You can also use your scroll saw to cut new or custom inserts.

How Long do Scroll Blades Last?

The general rule of thumb is that the best scroll saw blades lasts for around 30 minutes of cutting time.

The speed you are using and the material you are cutting will affect the lifespan of your scroll blades. If you cut too fast or too slow, you may break blades before they wear out.

Experienced woodworkers change their blades when they feel resistance or it takes and inordinate amount of pressure to make cuts. Their logic goes like this: the cost of the blades is much less than the cost of wood and other materials, so it’s better to change your blades than to damage your material.

Conclusion

Scroll saws are incredibly versatile tools that can make a variety of cuts, provided you have the right blade and use the right speed setting.